Ensure global supply chain best practices.

Supplier Assessment & Development Services

We help clients maximize their existing supplier base to meet production requirements. This includes working closely with suppliers to improve process and manufacturing capabilities, ensuring supply chain improvements and cost reductions are achieved.

- Supplier selection & development

- Supplier process certification

- Supplier audits (ISO and TS)

- Supplier assessments

- Supplier risk assessments

- Supplier training

- Supplier PPAPs

Safeguard the design process from conception to end of life by reducing failures at every step.

APQP Services

When properly applied, APQP forges a strong relationship between a client and supplier. This relationship is based on confidence in the quality of the product. Through consulting, we help clients develop two aspects of APQP: the prevention of failure on new product/services within the organization and APQP deployment for the supply chain.

- Undertake complete project & resource management

- Plan & define phase

- Product design & development phase

- Process design & development phase

- Product & process validation

- Feedback, assessment, & corrective action

- PPAP

- Manufacturing Plant Quality

- Software

- Consulting

- Training

Ensure the repeatability and capacity of the manufacturing process for all your products while streamlining PPAP activities.

PPAP Services

In today’s competitive manufacturing environment, cost control and first time right have become vital to a company’s success. We work with clients to deploy PPAP execution strategies per customer specific requirements by establishing a collaborative and learning environment between all parties. Our strength is to reduce the number of iterations from initial submission until full approval by training PPAP element owners and implementing checklists.

Customer PPAP, Supplier PPAP & Annual/Revalidation PPAP

- Create, review, verify, & Pre-approve PPAP submissions

- First article inspection (FAI)

- Collect documentation & drive on time execution

- Conduct source inspections, witness/verify run@rates & process audits

- IMDS approvals

- Product compliance REACH, RoHS, & conflict minerals

- Available PPAP software module to use as part of PPAP Services (or deployed at client) to enhance collaboration and provide full visibility/traceability for all your PPAP documentation.

Synchronize manufacturing activities with complete traceability.

Manufacturing Plant Quality Services

We help clients identify improvement and implement remedial techniques to overcome product defects and customer dissatisfaction. We find the root cause of a problem, devise a short-term fix, and implement a long-term solution for problem prevention.

- Incoming inspection

- Support plants & suppliers for supplier corrective action reports (SCARS)

- WIP or line inspections

- Sorting services

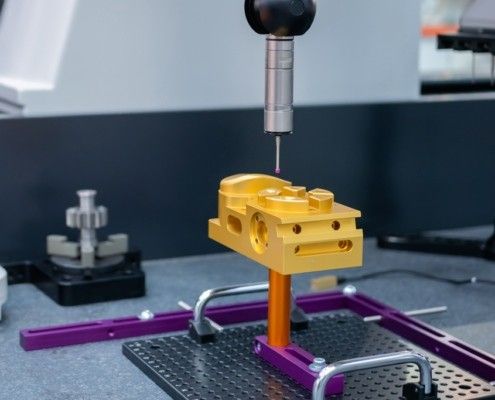

- CMM dimensional layouts & capability (CpK)

- 3rd party metallurgical inspections

- 8Ds, Pareto charts, & trends

- CMM programming

Promote opportunities and eliminate risks with problem detection and prevention.

Non-Conformance & Problem-Solving Services

- Non-conformance analysis – report the cost of poor quality (CoPQ) and conduct root cause analysis for non-conformances and rejections. Full management of sorting to identify the root cause of quality issues. Completely oversee 8D processes to review suppliers.

- Develop CAPA strategy – propose CAPA and SCAR to implement improvement strategies to eliminate sorting.

- Document revisions – update quality document such as PDF, PFMEA, control plans, and lessons learned database per action items.

Support services for reviews, make ups, approvals, and rejections of supplier dimensional layouts.

Dimensional Layout Services

Support services for reviews, make ups, approvals, and rejections of supplier dimensional layouts.

- Conduct dimensional inspections to meet given requirements.

- Monitor SPC inspection data from suppliers during PPAP and production.

Advisory services to create compliance programs that facilitate supply chain responsibility.

Compliance Services

Product Compliance

- Material composition – IMDS, ROHS, and conflict minerals

- Substance regulations – REACH and PROP 65

- Disposal – WEEE (waste electrical and electronics equipment) and ELV (end of life vehicle)

Plant Compliance

- Environmental, Health and Safety (EHS) compliance

- Master / Regulatory Compliance Management

- Create – Allocate – Review – Approve

- Incident / Near Miss Recording

- Location & Plant based Scoring and Compliance Dashboards

- Policy Portal, Supplier Compliance

- Emission Recording & Reporting

- Audit Management leading to CAPA

Custom training programs designed by experts for supply chain compliance.

Quality Training Services

As quality experts, we develop custom training programs for clients and suppliers with clearly defined learning objectives. Quality training is designed to ensure compliance with AIAG (North America) and VDA (Europe) standards. Training formats include onsite instructional and eLearning with coursework based on the real quality of your supply chain.

Quality Training Expertise

- DFMEA

- PFD

- PFMEA

- Control plans

- Measurement systems analysis (MSA)

- Initial process studies (CpK)

- SPC

- GD&T

- Ishikawa diagram and 5 Whys

- 8Ds

- Quality management systems

- Value stream mapping

- IATF

Empower QLMS eLearning Training Portal

Empower QLMS (quality learning management system) is a robust, secure cloud-based software that can be customized to meet any corporate training objectives. The tool provides companies with scalability necessary to conduct, manage, track, and report trainings globally.

- Multiple languages available

- Onsite and web-based applications

- Course catalogs

- Videos, audio, & presentations

- Online quizzes & assessments

- Certifications

- Dashboard reporting

- Real-time Q&A

- Email notifications & reminders

- Live webinars

Get the best talent for your quality-related roles.

Quality Staffing Services

Find the best talent to fill quality-related roles from deploying PPAP packages to facilitating studies related to quality management.

Examples of Positions

Quality Engineer Positions

- Reliability & Safety Engineer

- Supplier Quality Engineer

- Supplier Development Engineer

- Quality Assurance Engineer

- Plant Quality Engineer

- Continuous Improvement Engineer

- Advanced Quality Engineer

- Supply Chain Planning Engineer

- Quality Systems Engineer

- Continuous Improvement Engineer

- PPAP Engineer

- Value Stream Mapping Engineer

Quality Assurance Positions

- Inventory Control Inspector

- Document Control Specialist

- Auditor

- Quality Control Supervisor

- Quality Statistical Analyst

- PPAP Coordinator

- Plant Launch Coordinator

- Customer Quality Manager

- CMM Inspector

- Calibration Lab Technician

- CMM Programmer

- Environment Compliance Specialist

- IMDS Coordinator

- Plant Technician